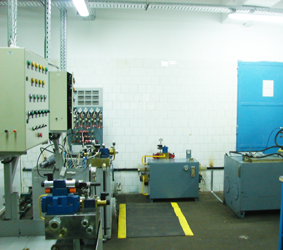

TESTING

LABORATORY of hydraulic equipment for high and

medium pressure

Fluid power field is

characterized by specialized equipment whose performances are

framed in terms of increasingly stringent requirements imposed

by technological practice worldwide.

Testing laboratory of hydraulic equipment for medium and high

pressure of INOE 2000 - IHP is dedicated to functional tests that

will lead to achieving realistic characterization of performances

of tested equipment;

Equipment under tests:

hydraulic valves RD6 ... RD20, hydraulic directional control valves

RD6 ... RD20, electro hydraulic servo valves for maximum 150 l/min.

The specialized stands are equipped with cutting edge devices,

the generation of working fluid is performed by modern pumping

modules that provide pumping rates between 0...170 l/min, maximum

pressure 350 bar; control and distribution equipment is included

in the data acquisition system so that the working parameters

can be adjusted directly by the user from within the testing application.

Monitoring of functional parameters is performed using the data

acquisition system that includes modern transducers to determine

pressure, flow, displacement, data acquisition boards, and computing

machinery. The specific testing applications are developed using

TestPoint platform.

It should be pointed out that to meet the requirements of European

directives, the functional tests on hydraulic equipment are performed

in accordance with the prescriptions inside the harmonized European

standard EN SR 982 which e

stablishes security

requirements related to hydraulic and pneumatic actuation systems

and their components.